Cycle time is the greatest possible time in which a stock item can be produced, and it may be quantified as time per component or unit. Production scheduling, inventory management, and manufacturing operations rely on cycle times. Cycle times refer to the rate at your organization’s goods or services reach the market.

This post will briefly tell you about the cycle time inventory management system. Let’s get started.

What is the cycle time process?

Cycle time is the time needed by a business to manufacture a product or provide a service. Understanding how to determine cycle time can assist you in improving your manufacturing operations. The whole time a company spends working on a project to generate products or services from start to finish is called cycle time.

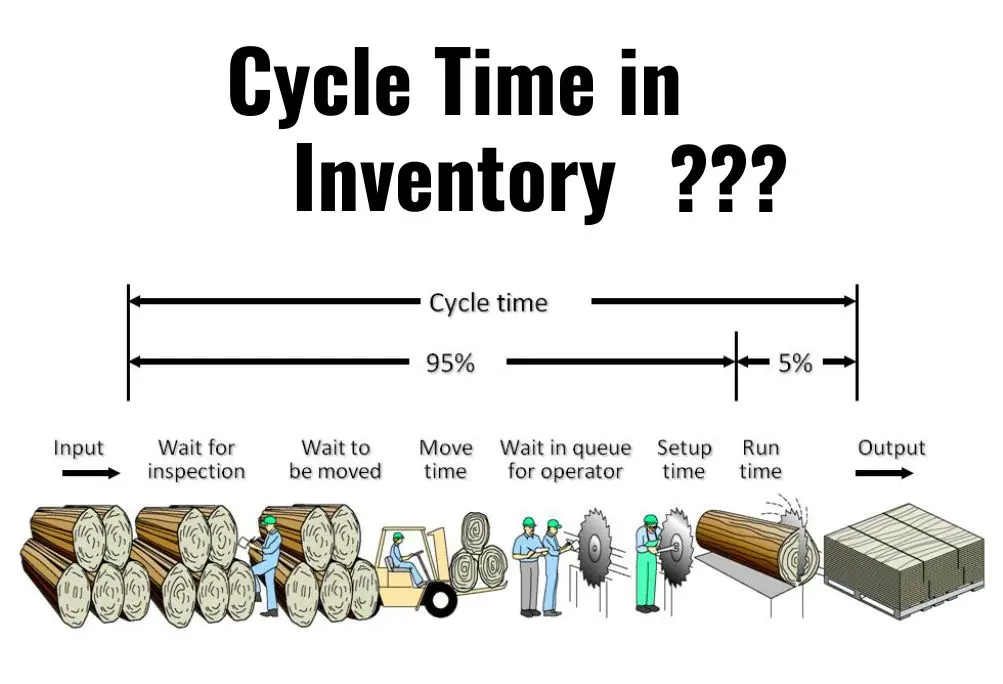

Cycle time is measured by combining the overall process time, inspection time, move time, wait time, and any additional time spent throughout the manufacturing process.

A cycle inventory is essential for a brand since it supplies the resources required to function daily. Due to the constant cycling of inventory, the firm must replace its routinely required inventory.

Inventory cycle time is the time it takes to generate and deliver a client’s order, commonly measured in days that will stop. It simply evaluates how quickly a corporation can complete the manufacturing or assembly process from start to finish transforming raw materials or components into a sellable product.

In a market where corporations like Amazon have established non characterized by instant or virtually instant pleasure, keeping your consumers waiting is a definite and male lose you not just a rapid sale but the business of the disgruntled customers.

The calculation of the time from when an item is started and when it is sent to the client. Cycle time is the amount of time spent working on a product or providing a service that is measured from the first task’s beginning to the final task’s finish. Cycle time combines both value-added and non-value-added time.

The essential term in the definition is because many businesses may use cycle time to represent the projected time spent working on the item. These two-time frames are frequently different.

What does cycle inventory mean?

Cycle inventory, also known as cycle inventory levels, is a part of a vendor’s inventory to meet regular sales orders. It is part of a company’s inventory.

Cycle inventory, also known as cycle stock, operating stock, or lot-size stock, is an important component of total inventory. It is that portion of inventory that enables the firm to satisfy the product’s regular demand. It is critical since this is the first thing a corporation does to fulfill our customers’ requests.

Cycle inventory is contextually connected to safety stock since both are components of a company’s on-hand inventory. The two terms are frequently used interchangeably. Cycle stock is also closely related to an organization’s inventory turnover rate.

Cycle inventory, sometimes called cycle stock or working inventory, is the portion of the total inventory available to satisfy normal demand. It consists of the items that will be employed initially to fulfill clients’ orders in a company’s normal business cycle. Cycle inventory refers to regularly sold and refilled products in a continuous loop.

Cycle stock is also essential to the company’s operations. This stock creates cash flows, which the corporation subsequently utilizes to pay its creditors. Cycle stock inventory is the amount of inventory a store or manufacturer keeps on hand during their normal business cycle to meet regular sales orders or predictions.

How do you calculate cycle time in inventory?

Cycle time inventory mainly focuses on demand rate; cycle time counts the time it takes to create one unit from start to finish.

Businesses may determine how long it will take to complete one product cycle by tracking and comparing production time to the number of units produced.

The cycle may be calculated by dividing the annual cost of sales by the average inventory level over the Year.

Thus, if the entire cost of manufacturing the firm’s products was $100,000 last Year and the average inventory was $20,000 in parts, the company has a five-year inventory cycle. Calculating cycle time inventory is very important for the firm to control the inventory.

The cycle time formula is a straightforward division and subtraction formula.

Total available production time/ number of units produced=cycle time.

For example,

A corporation works 35 hours per week, produces seven goods in that period, and has a cycle time of 5 hours.

Cycle time:5 hours×7weekly orders=35 hours per week

How does cycle time affect inventory?

Shortening product cycle times is one of the company’s supply chain management aims. Reducing cycle times allows you to respond to client demand more rapidly.

The cycle time of the goods is heavily influenced by the time of components required for product assembly. Reducing the buy lead and product cycle time is feasible by generating a safety stock for lengthy-time commodities.

Aside from the buy lead time, we must also deal with the minimum order quantity of the purchased products. This has an impact on order amounts and, consequently, component stock.

Based on data, ideal order amounts and safety stock files are found by using a mathematical model. The model gives insights into the outcomes of inventory management, such as inventory value expenses, performance improvement, and financial hazards.

The faster a company can determine its inventory cycle time, the sooner it can deliver its item to market. You will have a competitive advantage if your cycle time is shorter than your rivals, especially if you generate inventory stock swiftly supplanted by fast-changing features and functionality, such as electronics or smartphone devices.